Understanding 3D Printing Costs

The cost of 3D printing depends on various factors, including the materials, part complexity, and the steps involved in the process: planning, printing, and post-processing.

1. Planning

Our experts analyze and optimize each design file using a range of tools and software designed for 3D modeling and optimization. We offer minor adjustments free of charge, while more complex cases may require additional work. This is particularly important for scale models with many intricate details and components that need optimization to match the printer’s requirements.

2. Printing

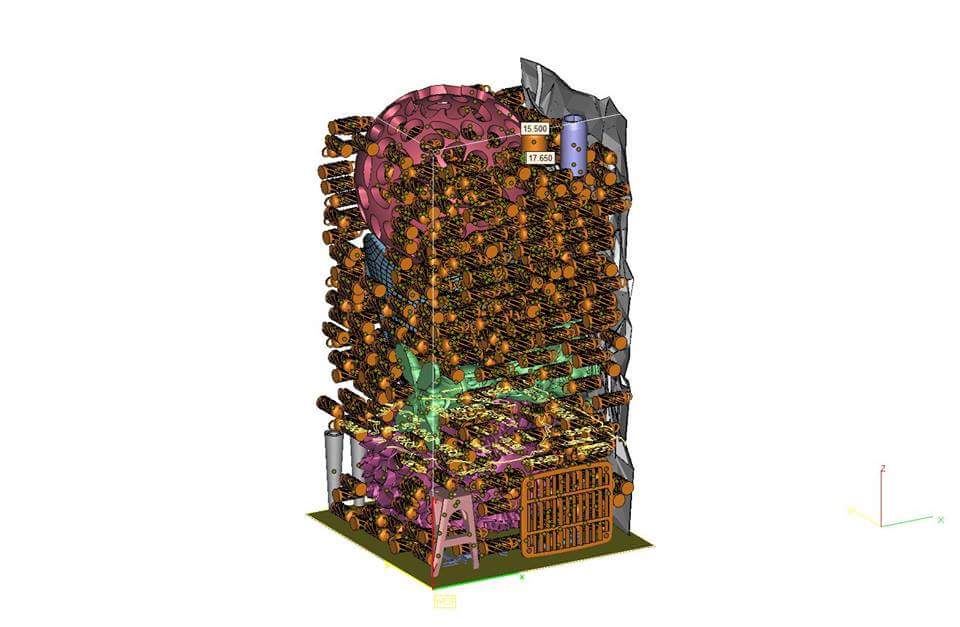

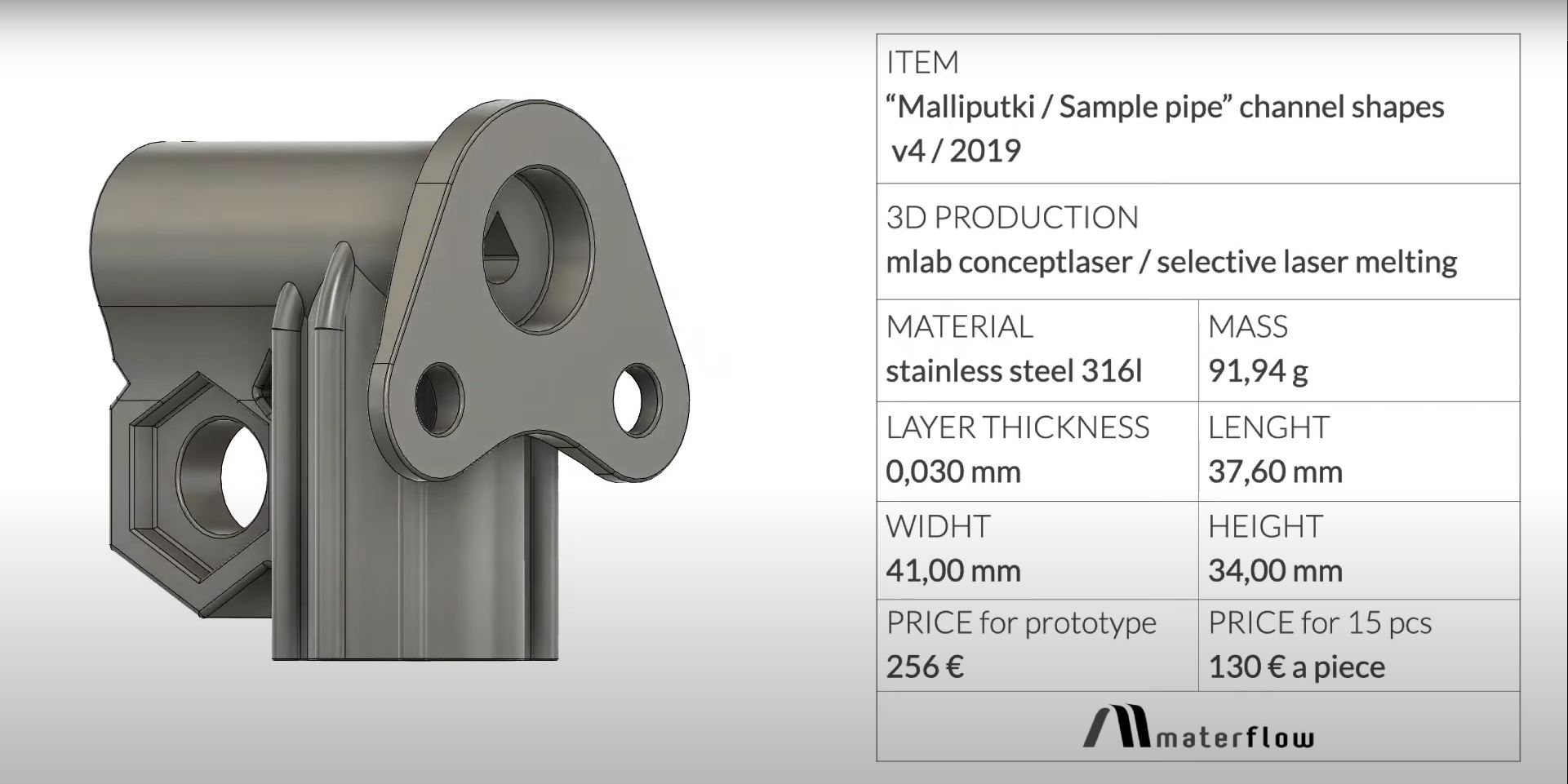

Parts are efficiently nested within the printer’s build chamber to maximize production efficiency. We aim for full production runs and can accommodate specific orientation requests. With powder-based SLS (Selective Laser Sintering) for plastics and SLM (Selective Laser Melting) for metals, optimizing part orientation and support structures can lead to significant cost savings.

3. Post-processing

Our post-processing services include removing excess print material, surface quality improvement, and optional finishing touches. We offer a range of treatments, such as glass bead blasting, coating, painting, dyeing, and vibratory polishing. For metal parts, we also remove support structures and polish the supported surfaces.

Materials & Nesting

Proper optimization reduces material usage and costs, while efficient nesting ensures cost-effectiveness. We help customers achieve optimal designs and production runs without compromising quality or functionality. This involves carefully planning the stacking of parts inside the build chamber to minimize raw material usage and maximize production efficiency.

Surface Treatments

We provide various post-processing options, including manual processes like painting and coating for high-end models, and automated, cost-effective treatments like dyeing and vibratory polishing.

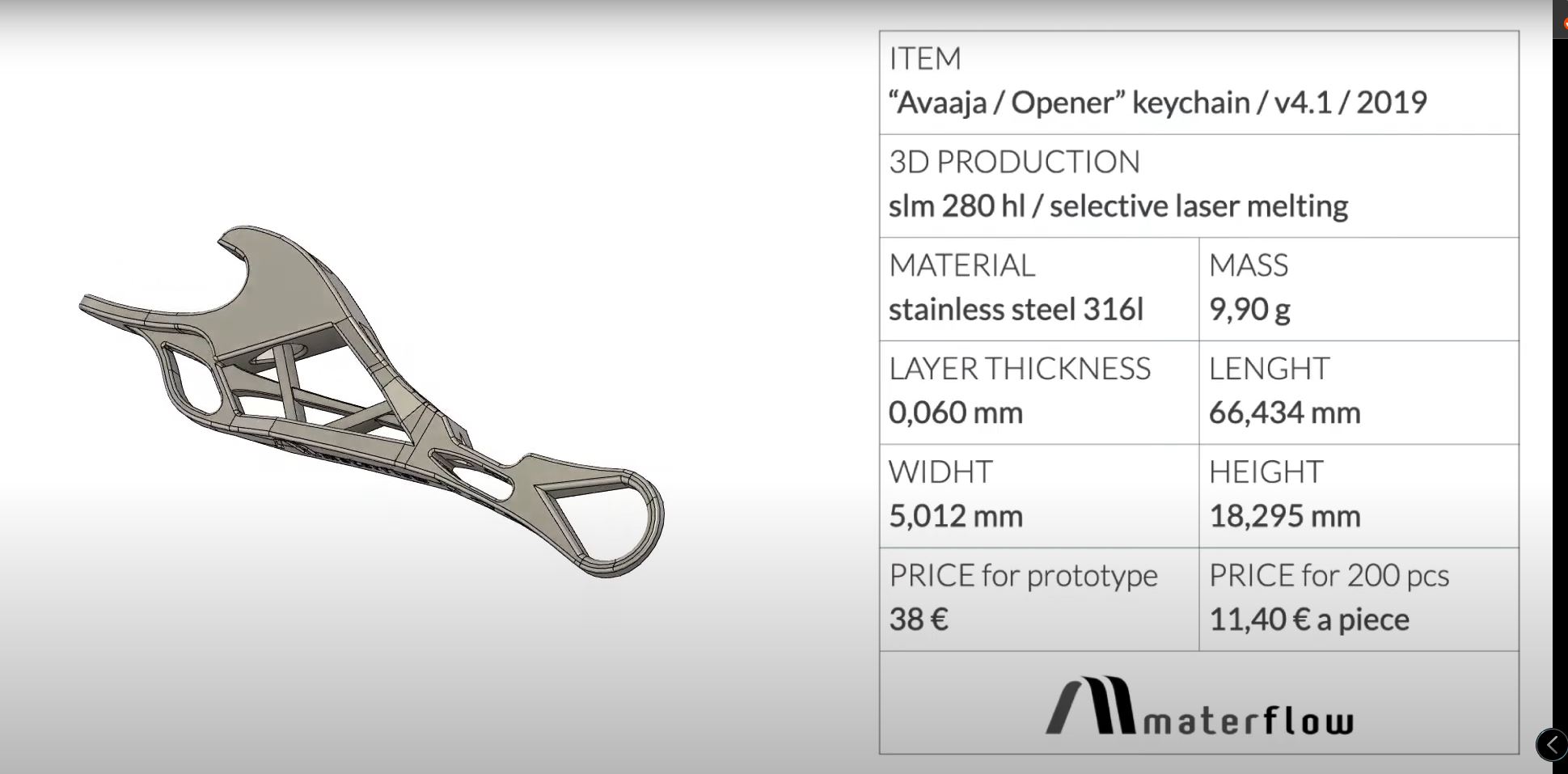

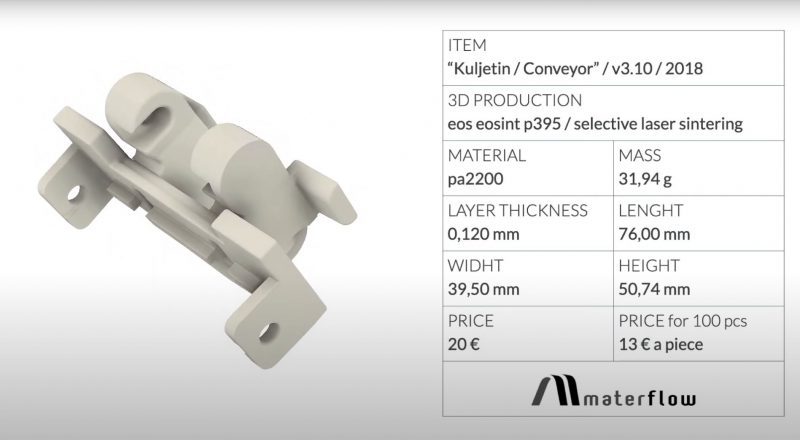

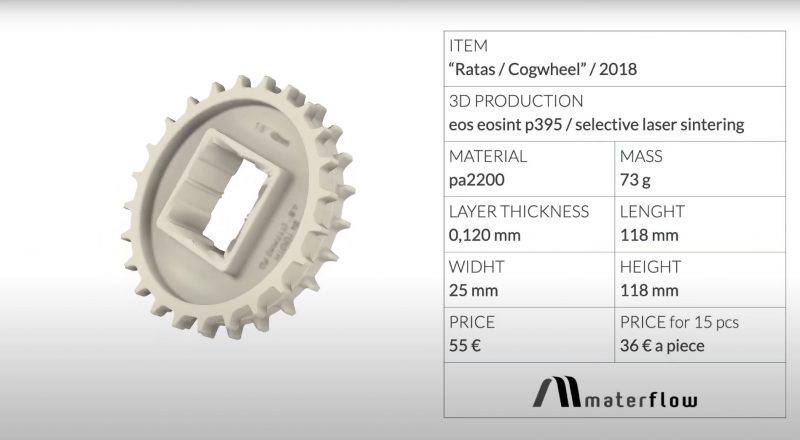

Sample Pricing for Metal & Plastic Products.

Materflow designs and produces 3D printed metal and plastic parts for industrial use. We also help our customers develop and implement 3D printing into their design and engineering processes. Contact